Table of Contents

ToggleIntroduction

Safety on the open water remains critical for every single voyage you undertake. I remember my first crossing in 1998; we underestimated our line needs, and it nearly cost us the boom. Safety is our utmost priority, and we assist you in finding the best marine rope for your specific journey. You will learn about the different fibers and materials used for superior marine ropes.

Why Is Selecting The Best Marine Rope Crucial?

Every maritime task you perform must be executed with a strict consideration for safety and efficiency. Selecting the best marine rope remains crucial to avoid potential disasters while out at sea. The use of a substandard rope often results in avoidable, expensive downtime for your vessels. Furthermore, a substandard rope poses significant injury risks to your hardworking crew members.

In terms of operational safety, that is a distinct risk you simply cannot afford to take. Have you ever considered how marine ropes help with strict OCIMF MEG4 guidelines?

Marine grade rope possesses the right characteristics and retains good tensile strength over a long duration. Inferior ropes leave you exposed because they degrade under harmful UV rays, and you damage your expensive deck hardware. Enhanced operational safety and efficiency are always the goals.

Selecting The Best Marine Rope For Vessels!

You will soon understand how to allocate the rope selection to a specific vessel type. This section focuses on computing loads and checking for compatible hardware for safety.

A. Assessing Vessel Displacement Metrics

Assessing a marine rope’s specific construction based on displacement attributes is an excellent place to start. The right parameters will mitigate the risks of equipment failure that can occur when completing the task. As the Cordage Institute notes, “Proper selection of rope requires an understanding of the application and the loads involved.”

1. Calculating Ship Design MBL

MBLsd Value

You need to determine the Vessel Design Minimum Breaking Load (MBLsd) value before purchasing. This value dictates the exact level of marine rope breaking strength you need for operations. Without this number, you cannot operate within a safe margin at the harbor.

105% Requirement

Marine rope working load limit values are specific to the rope you choose. For example, a rope MBL should be 105% of the vessel’s MBLsd value. This 105% value acts as a technical safety margin to prevent a line from snapping.

90 Tons

Imagine a vessel that has a standard 90-ton break load requirement for operations. In this case, a heavy-duty HMPE rope completes this task efficiently. It is ideal for replacing marine wire rope that is heavier and harder to manage.

Load Analysis

Make sure that you carry out a load analysis on your mooring rope. You must include the wind and current forces in your calculation. This ensures your marine rope performs under maximum stress and prevents expensive damage to the load.

2. Analyzing Tonnage Weight

Heavy Displacement

Make sure you make careful considerations for heavy displacement vessels in your fleet. These big class ships disperse a lot of forces on the marine dock lines. Heavy displacement ships need a 1 inch marine rope for overall stability in surges.

Gross Tonnage

Option selection will be impacted significantly by your vessel’s specific Gross Tonnage. The larger the Gross Tonnage is, the higher the required constituent elements of the rope. The line requires a commercial marine rope to ensure the line does not break.

Deadweight Calculation

Deadweight calculation should always be incorporated into the process of procurement. The larger the deadweight, the more heavy duty marine rope you need for safety. A 3/4 inch marine rope ensures stable anchoring is retrieved despite rough environmental factors.

3. Evaluating Deck Hardware

- Fairlead Size: You must always measure fairlead size for every line compatibility.

- Bollard Strength: You should confirm the specific strength rating for the bollard.

- Winch Capacity: You must check winch capacity to ensure safe installation workings.

- 15:1 D/d: You should never leave the 15:1 D/d ratio to chance. According to DNV GL standards, “The bending diameter ratio (D/d) has a significant influence on the service life of the rope.”

B. Determining Operational Load Limits

Next, you will evaluate operational working load limits and determine safe working load limits. You will use negative and positive safety factors and fault tolerances regarding marine ropes.

1. Establishing Working Loads

Safety Factor

The correct safety factors must be calculated so that the line does not break. This safety margin will balance and secure the marine tow rope. A 5:1 safety margin is common in the industry and increases safety for the crew.

5:1 Ratio

This is an industry standard for all towing and lifting to mitigate breaks. You possess the correct marine rope required for towing operations at sea. This is a vital industry standard for everyone’s safety on the working deck.

Safe WLL

Maximum Working Load Limits must be set on all your marine rope. This protects the core from fatigue and eliminates further deterioration of the line. This ensures that the line ultimately lasts its intended lifespan without sudden failure.

2. Verifying Tensile Strength

1140kN MBL

For larger vessels, the Working Load Limit should be set at 1140kN. This is the standard for the majority of large commercial vessel operations. To verify you have enough rope strength, a sample of 40mm HMPE should be used.

1500kN Force

Some tasks require the highest available marine rope strength of 1500kN Force. Dyneema rope is a perfect candidate for this specific high-load task. It is lightweight, not bulky, and performs very well under load for your crew.

High Tenacity

For better performance, select a marine rope made with high tenacity fibers. These fibers enhance the strength and insulate effectively against a dynamic load. Moreover, they outperform standard synthetic marine ropes in damage resistance during daily maritime usage.

Break Force

Always check the break force certified values in the documents you receive. This certifies marine wire rope is a suitable alternative for you. You ensure safety to avoid accidents at sea during the voyage and ensure compliance with ISO 2307. As stated in ISO 2307, “The determination of certain physical and mechanical properties of fibre ropes is essential for safety.”

3. Managing Shock Absorption

Dynamic Loads

You must manage dynamic loads in adverse weather to stay safe. This protects your vessel’s cleats from ripping out during a storm. Marine rope stretches to absorb the energy of the wave and structural damage is avoided during stress.

Surge Energy

To keep the vessel steady, the rope must absorb surge energy. Marine rope with polyester is recommended for this task as it has less stretch. However, marine bungee rope helps to create a buffer and reduce impact docking.

25% Elongation

Nylon has 25% elongation under load and still supports this parameter. 25% elongation is significant for elongation parameters for docking ropes. It dampens the motion of the boat when it is at the dock during heavy storms.

Force Spikes

Protection against potentially dangerous force spikes is a must for safety. A marine nylon rope does this really well by elongating under load. It also keeps the line from parting suddenly during a storm for your protection.

C. Calculating Rope Dimensional Sizing

You are also going to learn the correct sizing for your ropes here. This relates to measuring the diameter and determining the length for the vessel. Do you know exactly how much load your current cleat can handle?

1. Measuring Rope Diameter

Length + 2mm

For sizing, use the simple Length + 2mm rule for estimation. This simple formula determines what marine rope sizes are required for the boat. A 12m boat needs a 14mm minimum rope diameter to ensure suitable strength.

40mm HMPE

When it comes to commercial boats, consider the option of 40mm HMPE. This heavy duty marine rope is stronger than any other type. It takes the place of thick, heavy duty steel cable that is difficult to manage.

160mm Giant

Some tankers will need a 160mm giant rope size for operations. This is a significant type of commercial marine rope able to sustain force. You need to make sure your deck hardware supports this large diameter rope.

14mm Minimum

The minimum diameter should be at least 14mm for safety concerns. If the rope is any smaller, it lacks breaking strength. This can be dangerous if a huge storm comes up, as it risks sudden line failure.

2. Defining Required Length

1.5x Vessel

The rope should be 1.5x the vessel length for enough slack. This length is needed for dock lines and tidal adjustments. This way you make sure your marine dock lines can assist the vessel adequately at the port.

220m Standard

These days, commercial coils can be found in 220m standard lengths. This is perfect for large mooring rope winches found in ships. This way you make sure you have enough line to fit the drums of boats.

2x Beam

When calculating the proper length of the ship mooring lines, use 2x beam. This calculation mitigates excessive ship drift while loading at the pier. It ensures that the vessel remains tight against the dock during transfer operations.

3. Ensuring System Fit

- Groove Compatibility: You must check your winch drums for proper groove compatibility.

- Chafe Clearance: You should check if there is enough chafe clearance available.

- Splice Room: You must check your cleats for enough splice eye room.

D. Evaluating Environmental Resilience Factors

You will have to assess how the rope stands up to marine irritants starting with UV. We will then assess for heat and abrasion resistance. I once left a poly-line out for a full Florida summer; by August, it crumbled in my hands like dry pasta.

1. Assessing UV Degradation

160 Days

Most regions have a standard season length of about 160 days. Your UV resistant marine rope has to make it across that threshold. Fibers that remain untreated will weaken in the sunlight and lose strength over time.

UV Stabilization

Your rope must have a UV stabilization treatment for long life. This protects the rope and is a benefit of marine grade polyester. The rope UV stabilization treatment protects fibers from being broken down and becoming brittle.

300 Hours

Every month, our marine ropes endure over 300 hours of sunlight. However, polyester marine ropes withstand this exposure while polypropylene degrades. Thus, you must pick materials that are capable of withstanding solar radiation for the long haul.

2. Analyzing Abrasion Risks

Friction Coefficient

When it comes to marine ropes fitted to winches, low friction is preferable. HMPE ropes move easily across surfaces, thereby preventing friction. This sustains the rope from losing fibrous materials within itself during heavy winching operations on the deck.

Chafe Guards

Never forget to use chafe guards at the line contact points. This extends the life of your rope with abrasion resistant qualities. It prevents the line from sawing on the chocks, which is critical for safety. According to Samson Rope’s user manual, “Abrasion is one of the most common causes of rope failure and must be monitored closely.”

Rough Edges

Before you moor, always check the hardware for sharp rough edges. These can damage even the strongest marine rope within a single day. Smooth out these surfaces with a grinder to prevent damage to your synthetic marine rope.

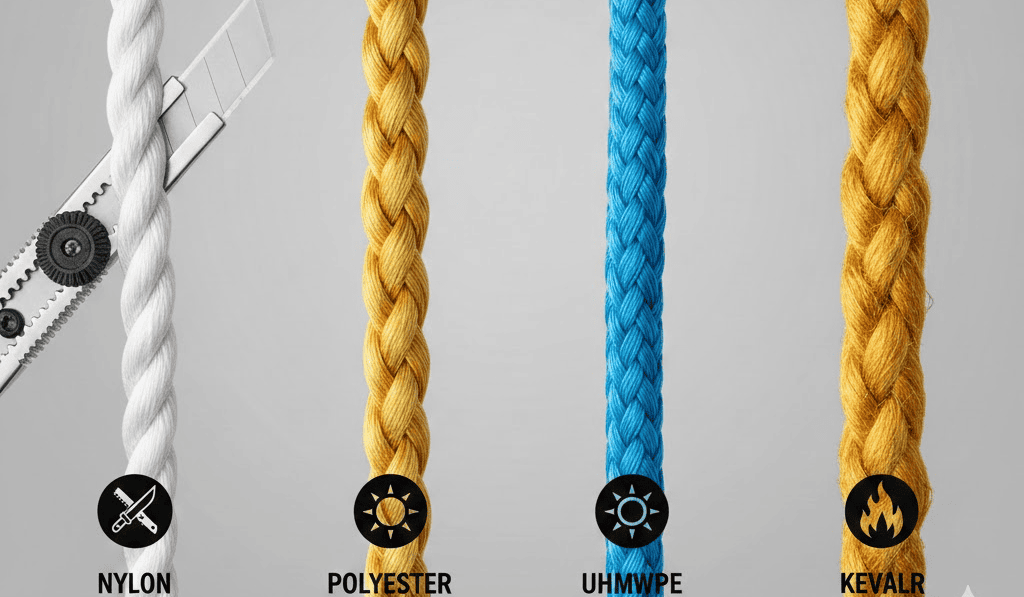

Cut Resistance

Cut resistance and resistance to sharp edges are also critical factors. Of all synthetic fibers, Kevlar rope is best at avoiding cuts. This means you ensure safety in salvage recovery operations at sea involving sharp debris.

3. Considering Thermal Limits

145°C Melt

Winch friction heat must be monitored carefully by the deck crew. Ropes made with UHMWPE rope have a very low melting point. If the rope gets too hot, you are risking damage to the marine rope core.

500°C Kevlar

It is very impressive that Kevlar rope protects up to 500°C. You use the aramid rope to protect the load-bearing core. You use it as a cover for high temperature applications where friction heat is a major concern.

Heat Treatment

It is best to use ropes with heat treatment applied to them. This enhances the Dyneema rope thermal stability at high temps. You ensure the best marine rope will perform under high temps without melting or failing.

E. Analyzing Total Cost Ownership

This section will show the true cost of your ropes over time. The best marine rope will be a smart investment for your company. Have you calculated how much frequent replacement costs you in labor alone?

1. Estimating Service Lifespan

5 Years

This is for the maintenance of the ship’s rope on deck. You will need to retire the rope before 5 years. This prevents damage failure and ensures that your mooring ropes for boats remain safe for daily use.

10 Years

With proper care, a rope can last a decade or more. The longevity of this rope keeps mariners loyal to Duracordix. Using quality marine ropes is a win for the owners as it does not limit value.

Cycle Testing

You can trust the cycle testing data to provide accurate results. It proves that quality marine ropes withstand repeated use without failure. This data helps you make informed decisions about the best marine rope for your specific needs.

2. Calculating Investment ROI

20% Savings

You can perform a 20% savings calculation over time for the budget. This is because quality marine ropes are replaced less frequently. Duracordix provides value for the marine rope price. This saves your operational budget significantly.

Reduced Labor

There is a reduction in labor costs with lighter ropes on deck. Your crew can move quickly with the synthetic marine rope. This greatly improves the overall operational efficiency on deck for everyone involved in the daily operations. Back when we used steel cables, it took four of us to move a line; with synthetics, two of us can handle it easily.

Lower TCO

When using synthetics, you achieve a lower Total Cost of Ownership. They last longer than steel and are cheaper than other fibers. Cost-effective ropes mean savings every year. You partner with the best value marine rope suppliers.

3. Reviewing Maintenance Costs

- Zero Lubrication: HMPE ropes provide zero lubrication maintenance for the crew.

- Freshwater Rinse: A freshwater rinse is effective against accumulated dirt. Marlow Ropes advises that “Salt crystals can act as an internal abrasive, so regular washing with fresh water is recommended.”

- Easy Splicing: Quick repairs mean you learn how to splice marine rope.

F. Verifying Safety And Compliance

You will verify your ropes meet safety standards concerning snap-back zonesand certifying that you have the best marine rope and it is compliant.

1. Mitigating Snap-Back Zones

80% Reduction

HMPE achieves an 80% reduction in recoil energy during a break. This lowers the potentially dangerous snap-back zones present on the deck. In this regard, Dyneema rope is safer than steel and protects your crew from injuries.

Low Recoil

For safety, you must select ropes that are low recoil by design. This is because nylon rope stores too much energy under tension. On the other hand, UHMWPE rope drops dead when cut, raising deck safety.

Energy Absorption

You minimize the energy stored in the line during operational procedures. This prevents dangerous line failure due to line parting under load. This means the best marine rope is extremely supportive and safe for the working crew.

2. Confirming Class Certifications

ABS Class

An ABS Class Certificate is a requirement for your ropes today. This ensures marine rope suppliers are trustworthy and legitimate. This ensures a level of manufacturing quality and you have ensured the rope is compliant with standards.

DNV GL

Stamps from DNV GL appear on some ropes as international certifications. It vouches for quality marine ropes, so you can trust them. Trust the technical specifications that come with these certifications for your peace of mind.

Lloyd’s Register

Compliance with Lloyd’s Register concerns all your lines on the vessel. It is essential for the insurance of the vessel to hold. It certifies the marine rope is of sound integrity and strength for work. Lloyd’s Register states that “Certification provides assurance that the equipment meets the required standards for safety and performance.”

ISO 2307

You must always retain an ISO 2307 test report for records. It demonstrates compliance with all standards of global testing protocols. This standard measures the rope’s diameter and strength so you can be sure of the capacity.

3. Adhering To MEG4

- LMP Plan: You must implement an LMP Plan for your fleet without delay.

- Retirement Criteria: Ropes must be strict on retirement to prevent failure.

- OCIMF Guidelines: It is important to comply with OCIMF Guidelines continuously.

Comparing Materials For The Best Marine Rope!

You will compare the different fiber types in this section to assist you in selecting the correct material for operations. You have the best marine rope material for your particular application.

Nylon Elasticity

The best type of rope to use for tough marine uses is marine nylon rope. It features special elasticity that is also resistant to algae. But why is this the case for your boat? The rope can stretch to 25%, which is a considerable capacity for difficult sea conditions.

However, this elasticity does negatively impact the shock load absorption on the hardware. This specific rope does have a tendency to lose wet strength when submerged. There is a considerable snap-back risk, which is the worst part. This is why you have to be careful when using it as dock lines and anchor rope.

Polyester Durability

Marine grade polyester rope is reliable due to its durability. Fibers are generally resistant to UV degradation from the sun. Marine grade polyester rope retains its strength even when it is wet. It has low stretch which means that stability of the vessel is retained. Also, it is more resistant to abrasion than nylon is. Hence, all marine grade rope that has low movement usage for rigging and permanent mooring lines is the best option.

Polypropylene Buoyancy

Choose polypropylene marine rope if you want a light rope that floats. It has a specific gravity of 0.91 so it will float on the water. For this reason, it is the best option for rescue lines and marine rope which needs to float. The downside is that it is poor UV resistant and degrades quickly when exposed. This is the reason it is best used for temporary usage or as a marine tow rope.

Aramid Heat

In case of extreme heat during your job, using aramid rope is your best option. They can withstand temperatures of 500°C, so even they won’t melt. They hold up well in winch lines since they are heat resistant. They don’t melt even when abused heavily, and they are extremely cut resistant.

However, they do have poor UV deflection. Luckily, like most of these ropes, they are jacketed, which makes them ideal offshore ropes. As Teijin Aramid notes, “Aramid fibers offer excellent heat resistance and dimensional stability.”

Mixed Fibers

If you are looking for an average balanced performance, consider looking into mixed fibers. These ropes are blends of polypropylene rope and polyester. This way you have the buoyancy of poly, and the durability of polyester. Therefore, the rope is a strong floating line with UV protection. The mixed rope makes it also cost-effective. Due to these reasons, this rope is well known for general purpose mooring rope.

Synthetic Blends

For specialized purposes, some customers opt for the advanced synthetic marine rope blends. These ropes have the properties of being incredibly strong, low-creeping, and highly resistant to moisture. They are good for deepwater lowering. Furthermore, they are lighter than steel marine wire ropes, making for ease of handling in any lowering operation. These blends are the future of marine ropes.

Wet Strength

When considering the ropes, the wet strength of your rope is critical. When submerged, nylon marine rope loses about 10-15% of its wet strength. On the other hand, Polyester marine rope and Dyneema rope do not lose any strength at all. This becomes critical when considering underwater lines so you can avoid unexpected failures of lines during storms. Always keep this technical parameter in mind.

Creep Resistance

When it comes to permanent loads, you do need to look at the creep resistance. Creep is the slow extension of a fiber when it’s held at a constant tension. Polyester rope has good creep resistance. HMPE ropes have a little more creep resistance than polyester, but some creep resistance still exists. This causes problems for the longevity of a mooring rope for boats.

| Technical Parameter | Nylon (Polyamide) | Polyester (PET) | Polypropylene (PP) | HMPE (Dyneema®) | Aramid (Kevlar®) | Mixed Fiber (Poly/PP) |

| Specific Gravity | 1.14 (Sinks) | 1.38 (Sinks) | 0.91 (Floats) | 0.97 (Floats) | 1.44 (Sinks) | 0.99 – 1.10 (Neutral) |

| Elongation at Break | 15% – 28% | 10% – 15% | 18% – 25% | 3% – 4% | < 4% | 16% – 20% |

| Melting Point | 215°C – 260°C | 260°C | 165°C | 145°C – 152°C | > 500°C (Decomposes) | 165°C (PP Component) |

| Wet Strength Retention | 85% – 90% | 100% | 100% | 100% | 100% | 100% |

| UV Resistance | Good | Excellent | Poor | Excellent | Poor (Needs Jacket) | Very Good |

| Abrasion Resistance | Very Good | Excellent | Fair | Superior | Excellent (Cut Resistant) | Good |

| Primary Application | Dock/Anchor Lines | Rigging/Mooring | Towing/Rescue | Heavy Lifting/Towing | High Heat Winches | General Mooring |

Technical Specifications Comparison of the Best Marine Rope Materials!

Top Applications Requiring The Best Marine Rope!

Every task has its best options. This helps you decide what to buy for your boat. You ensure that your best marine rope is allocated to the right task.

Mooring Operations

You want the best marine rope to carry out safe mooring operations. The optimal ropes are HMPE or high-quality polyester. They are strong, yet, very light for the crew. You get these performance lines from Duracordix. They reduce the physical strain on your crew. They are also salt and chemical resistant. For shock absorption, marine rope tails are recommended. This combination ensures your boat is safe at the dock.

Towing Hawsers

For towing, a strong marine tow rope is a must. This requires a lot of breaking strength. Dyneema rope is the lightest and best rope for marine towing. It floats, which is a big plus as you won’t get prop wrapped. For shock, some people use large nylon rope stretchers. This setup guarantees safe and efficient towing operations at sea while protecting the tug and the tow.

Anchor Lines

Trusting the marine rope you select for your anchor is critical. You should only choose nylon as it is industry standard anchor rope. There is natural stretch in the rope that will absorb the shock from the waves. This ensures the anchor will not get dragged. The rope is easy to splice and inspect. For larger vessels, braided marine rope is more suitable for handling.

Offshore Rigging

Heavy duty marine rope is a requirement for offshore rigs. Steel is being replaced with UHMWPE rope as it is more user-friendly and safer to handle. As rope goes, it is a very good one as it does not get damaged by corrosion. In the marine rope industry, Duracordix is a reputable supplier. This helps to aloft the overall weight of the rig and improve stability. I’ve seen riggers work twice as fast since we swapped the heavy wire for HMPE; the fatigue factor is gone.

Deepwater Deployment

If deepwater deployment is required in your work task, you will have to acquire specialized lines. Marine wire rope strands will overall be very heavy. This will not be ideal for the more complex work for managing lines. The best alternative is high-modulus synthetic marine rope. For buoyancy, it is perfect neutral. In essence, it will be able to float a sufficiently heavy marine rope.

Salvage Recovery

With respect to salvage recovery, one’s rope has to perform well. Strength is paramount, and you need the proper marine rope for boat lifting. These HMPE ropes supply the best strength-to-weight ratio you will find on the market. Even better is the fact they float, which is an advantage for you. Another key feature is cut resistance, as you will have to deal with dangerous debris.

Winch Lines

Replace your steel cables with synthetic marine ropes. Dyneema is one of the best options. It never kinks or bird cages when winding onto your drum, like wire does. You also avoid the risk of wire splinters. With Duracordix, you get excellent heat protective coatings and good winch lines. The marine rope you use will maximize your winch system and ensure safer operations on the deck.

Docking Systems

With docking systems, optimize your docking system with the correct line. Polyester marine rope is the best choice for dock lines. It will not scuff the finish of your boat with its soft touch. For the marina, polyester marine rope resists UV damage for a line that offers a long-lasting rope. The correct size marine dock line is also essential. You protect your investment with the right rope.

Analyzing Construction Styles For Optimal Performance!

You will learn the primary construction types and how they affect the use of different types of rope. This includes the rope braids, twists, and plaits. I still teach my new deckhands how to splice a 3-strand first; it’s the foundation of all good seamanship.

12-Strand Braid

In a twelve-strand braid, strength efficiency is maximized. The standard construction for UHMWPE rope is a braid of 12 strands. It is also torque-free and will not twist under a load. This means it is the best marine rope for use with winches. Splicing marine rope is virtually effortless. You will learn how to do this easily. This rope design is the best for marine grade rope.

8-Strand Plait

For the 8 strand plait, the relatively large vessels work best for mooring. This marine rope will always hold the capstan. It is still flexible after many years of use. It is often used for mooring hawsers and anchor rope. It is not kinked like a rope of strands that are twisted. For this reason, it is a great choice for commercial marine rope.

Double Braided

You should use a double braided marine rope when you are mooring your boat. This kind of rope has a cover and a core. The cover protects the core from losing strength from wear. This double braid is durable enough to suffer the chafing of continual marine use. High-quality rope can be found from Duracordix. They provide soft rope that is easy to manipulate for secure dock lines.

Torque Balanced

To prevent problems while using the rope, you should ensure that it is torque balanced. This ensures that the line will not rotate while under tension. Braided marine rope has torque balance by nature. Twisted 3 strand marine rope, however, is not torque balanced. Torque can create hiccups and kinks. This weakens the line a lot. You need a stable rope for lifting and important tasks. According to Yale Cordage, “Torque balanced construction neutralizes the tendency of the rope to rotate under load.”

Parallel Core

Ropes that have a reduced stretch can benefit from a construction that is parallel core. The core fibers are not twisted inside the rope. This maximizes the rope’s tensile strength. It is often used in sailing halyard rope. A cover protects the core. It is high-performance marine rope construction. You ensure minimal elongation in your rigging.

Single Braid

A single braid is a hollow tube of fiber. Dyneema rope is often single braid. The braid is easy to check for internal damage. Eyes are easy to splice. Its lightweight and flexible nature makes it the best rope for sheets and control lines. You get efficient handling.

Wire Layouts

Comparison of the synthetics is assisted by an understanding of wire layouts. Marine wire rope has intricate strand geometries. These are copied by synthetics for strength, but with less weight. You switch heavy wire for light synthetic marine rope. This drops the deck load. This upgrade addresses corrosion issues. Access the best rope technology for marine.

Strand Geometry

The rope’s properties are determined by the strand geometry. Braid tighter, and the harder and more abrasion resistant it becomes. Softer looser braids snag more easily, but are softer. Geometry in rope also impacts the feel the most. Find a balance of flexibility and durability. Quality rope, which performs perfectly in its intended marine application, is the result of engineering optimal geometry.

| Construction Type | Structural Geometry | Torque Characteristic | Splice Complexity | Abrasion Resistance | Elongation Profile |

| 12-Strand Braid | Hollow Tubular | Torque-Free (Neutral) | Class 2 (Easy) | Moderate | Low (<4%) |

| 8-Strand Plait | 2×2 Square Cross-Section | Torque Balanced | 4-Tuck (Moderate) | High (Snag Proof) | High (>20% Nylon) |

| Double Braid | Load-Bearing Core + Cover | Low Rotation | Class 1 (Complex) | Superior (Jacketed) | Medium (10-15%) |

| Parallel Core | Unidirectional Fiber Core | Zero Torque | Cover Dependent | High (Protective) | Ultra-Low (<2%) |

| Single Braid | Interlocking Strands | Low Twist | Lock-Stitch Required | Moderate | Variable |

| Wire Rope Layout | Helical Metal Strands | High Rotation | Mechanical Swage | High (Corrosive) | <1% (Static) |

Technical Construction Metrics for the Best Marine Rope!

Emerging Trends In Synthetic Fiber Technology!

Discover innovative marine ropes with smart technology and eco-friendly fibers. Dominate the market with the latest marine rope advancements. Are you ready to integrate smart sensors into your LMP?

Smart Sensors

The technology of smart sensors will soon be incorporated into ropes. These chips monitor load and heat. They provide warnings before the marine rope fails. Integrated with the LMP Plan, this technology elevates safety and inspection standards. These sensors give you the ability to operate with data-driven safety standards.

Bio-based Fibers

The first fully bio-based rope products made from renewable resources will be available soon. This marine rope innovation helps to minimize the carbon footprint of marine rope suppliers. The ropes made from these fibers are eco-friendly and perform comparably to the conventional fossil fuel ropes. This marine rope innovation meets the growing global green initiatives. As DSM Dyneema announces, “Bio-based Dyneema fiber helps to reduce the carbon footprint without compromising on performance.”

Recyclable Materials

Whenever possible, select ropes made of recyclable materials. The industry is entering a circular economy where old mooring ropes get recycled into new ropes. This eliminates marine waste. This is a trend supported by Duracordix as well. Choosing a rope made of recyclable materials reduces ocean pollution responsibly.

Hybrid Constructions

Use hybrid constructions for improved performance. These ropes merge carbon and HMPE fibers. They give a combination of the best characteristics: extreme heat resistance and extraordinarily high strength. This addresses very particular and challenging engineering issues. You receive fully bespoke solutions.

Coating Innovations

New coatings give protection and new innovative benefits. Advanced polyurethane coatings defend against abrasions and UV damage. The Dyneema rope’s lifespan increases dramatically. The result is a smoother rope of better durability. It’s a tough rope that is easier to handle in winches. Your marine rope can withstand the elements.

Weight Reduction

Expect the ropes to progressively get lighter. New marine rope processing technologies are emerging that value operational speed. This is a very important feature of the best marine rope. Improved speed with fewer crew members. It’s a key benefit of the best marine rope.

Strength Increases

The increase in strength when it comes to fiber improvement is astonishing. Molecular engineering creates new stronger polymers. A thinner UHMWPE rope is able to hold more. You are able to go with smaller diameters. This saves more space in the drum. The breaking strength of marine rope is continually improving.

Digital Monitoring

Digital Monitoring is adopted into your fleet. Each rope has usable tracking history. You can track your mooring rope history. It predicts retirement date accurately. It is digitally integrated with Duracordix. You can prevent the use of defective ropes which helps to improve safety.

FAQs – Bonus!

What Is The ISO 2307 Testing Standard?

ISO 2307 is regarded as the testing standard for fiber ropes. It outlines specifically the marine rope breaking strength as well as the diameter and elongation. You should always ask for a certificate which describes this standard. This ensures the marine rope purchased has proper documentation and will meet the safety requirements.

Does Mblsd Determine Rope Diameter Selection?

For sure. Mblsd means that one needs to have a rope that has a breaking strength of more than 105% of that value. 90-ton loads require either a 70mm polyester marine rope or a 42mm of HMPE rope. It’s a function of the best marine rope material’s diameter.

Why Use Bio-Based Fibers In Marine Ropes?

These provide a great sustainable option. Bio-based fibers supplement the carbon footprint of marine rope suppliers. It retains the great useful performance of a marine rope. In this sector, Duracordix is a frontrunner. It enables your organization to achieve its environmental goals. Thus, you help the marine industry to have a green future.

What Is The 15:1 D/D Bending Ratio?

15:1 D/d ratio is one of the rules of MEG4 that you cannot overlook. The diameter of the hardware (D) must be 15 times that of the diameter of the marine rope (d). It is meant to prevent the smashing of the fibers. It prolongs the rope’s service life. You have to ensure that your fairleads meet this technical specification.

Do HMPE Ropes Resist 145°C Friction Heat?

No, standard HMPE ropes melt at about 145°C. Friction from winches can surpass this temperature. For these cases, ropes with specially designed heat-resistant aramid covers are required. These aramid covers protect against catastrophic failure from internal melting, providing a higher safety level for fast winching operations.

How Does Creep Affect HMPE Mooring Longevity?

Creep is a slow, permanent elongation phenomenon that occurs under constant load conditions. Measurable creep occurs in all HMPE ropes after some time under constant load. This permanent elongation can become problematic over time, especially when affecting permanent mooring systems. This has to be thought about when making your LMP Plan.

What Is A Line Management Plan (LMP)?

LMP Plan is an officially required logbook for your ropes. It details the history, inspection, and location for each mooring rope. It helps you determine when a line should be retired. This is a requirement for tankers from OCIMF MEG4, ensuring that they are efficiently and safely managing their marine ropes.

Is Specific Gravity 0.97 Buoyant In Seawater?

Yes, because a specific gravity of 0.97 is less than 1.025 of seawater. Dyneema rope and polypropylene rope will float. The line of the floating property prevents prop entanglement, is preferable in marine tow rope applications, and makes handling easier.

Does Nylon 6.6 Absorb 10% Water?

Yes, nylon 6.6 absorbs moisture. This moisture reduces the rope’s wet strength by 10-15%, which needs to be accounted for in anchor rope sizing, and it adds weight to the rope. However, the elasticity of nylon makes it the best marine rope for shock absorption.

What Is The Friction Coefficient Of HMPE?

HMPE also has a very low friction coefficient. HMPE is also very slick, like Teflon. This reduces internal abrasion, but it can also slip on winches, which is why a polyester marine rope cover is sometimes needed for grip. Slip and grip balance for efficient handling characteristics is what Duracordix designs these ropes for.

Do Aramid Fibers Decompose Above 450°C?

Aramid Fibers such as Kevlar are also very heat resistant. Above 450 degrees Celsius, they do not melt, but they do decompose. This makes them ideal for marine grade rope for high-heat zones. This also explains why, for extreme marine environments, these fibers are used to sheath the core.

Is 12-Strand Braiding Torque Balanced?

Yes, 12 strand braiding is indeed torque balanced by nature. The left and right twists balance each other out. There is no kinking or rotation under load, which is better than 3 strand marine rope. It is a safe, stable line and is the construction of choice for heavy duty marine rope.

What Is The Recoil Reduction In HMPE?

For HMPE, 80% recoil reduction is standard. It has low stretch and therefore very little energy is stored. If it breaks, it drops and does not violently snap back like nylon marine rope does. To reduce the snap-back zone, you choose HMPE. It saves lives on the deck.

Does UV Stabilization Extend Rope Lifespan?

Rope UV stabilization is very important as it protects synthetic ropes from harmful UV rays. Without it, a polypropylene rope fails and degrades in 6 months. Duracordix treats UV resistance on all ropes so you receive a marine grade rope with sun exposure and UV resistance.

What Is The TCO Of Synthetic Ropes?

The TCO of synthetic ropes is less than that of steel, believe it or not. The initial price of marine rope is more; however, its life span is greater. With less maintenance and labor needed throughout the ropes life span, Duracordix delivers a cost-efficient rope that offers a smart financial decision.

Conclusion

When it comes to core safety options for your vessel, you know the quality materials needed for reliable performance at sea. Maintenance to your equipment is a must, and it significantly prolongs the life of used equipment. Don’t choose the cheaper options. Protect your large vessel and get the best marine rope you can trust from Duracordix.

About The Author

Moses Xu

Hi, I’m Moses Xu, VP and Marketing Director at Duracordix. With 10+ years in high-performance synthetic ropes and netting, I specialize in export trade and marketing. Whether it’s HMPE, Kevlar, or nylon ropes, I’m happy to share insights and connect!